CASE STUDY

Differences in pneumatic tube system impact on blood samples emphasizes need for quality control

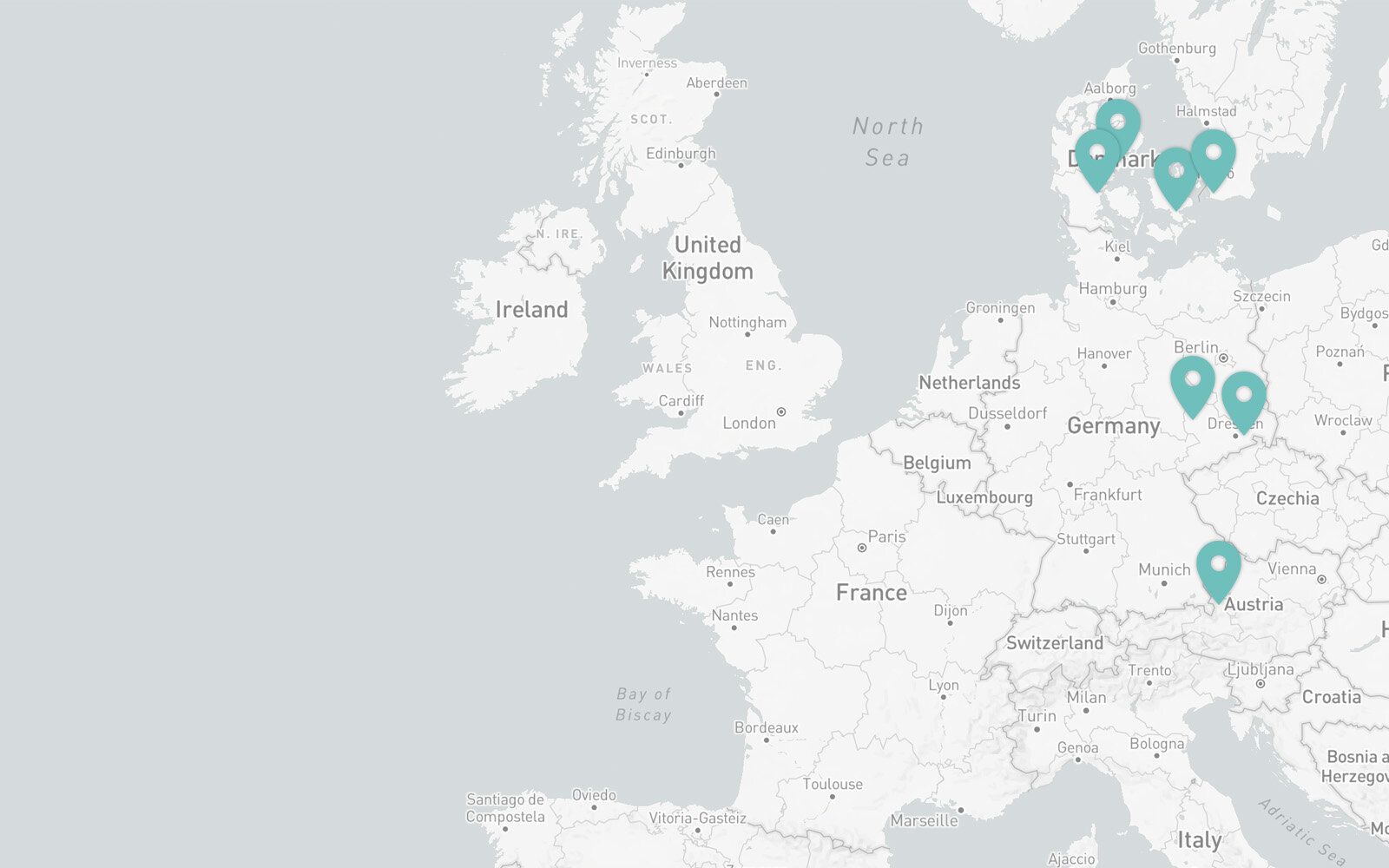

Hospitals in Austria, Germany, Sweden and Denmark · 400-2,400 Beds

Hospitals in Austria, Germany, Sweden and Denmark · 400-2,400 Beds

- Nybo et al. 2017

Every Pneumatic Tube System (PTS) installation is unique, which has impacts beyond sample turn-around-time. The manufacturer, number of zones in the hospital, canister design, sending speed, and individual twists and turns in the system all contribute to the overall experience of the samples during transit. Studies have independently shown the positive relationships of both speed and system length with resulting hemolysis (Nybo et al. 2017, Streichert et al. 2011). But in practice, how much does the uniqueness of a PTS installation affect the quality of blood samples that are being transported?

Motryx tested pneumatic tube systems in seven different hospitals in Europe with VitalQC to measure how differences in design and installation affect the quality of blood samples that are transported

Across all hospitals, VitalQC measured PTS vibration that varied by >500%: a sample sent via PTS in one hospital experienced 18 times more total vibration compared to a sample sent in another hospital. The result? VitalQC expects hemolysis to be seven times more likely in the hospital with the highest vibration compared to the hospital with the lowest vibration.

This multi-institute comparison emphasizes the need for each system to be validated for the safe transport of specimens. No two systems are the same, and they can each be checked for risk of hemolysis with little to no blood.

PTS vibration varied

between hospitals

Hemolysis is

more likely at the hospital with highest vibration

Samples experienced up to

more vibration

The best way to experience the value of VitalQC is in your own space.

We are happy to facilitate this demonstration and will provide you with a free, no-commitment trial.